Plyform Panels

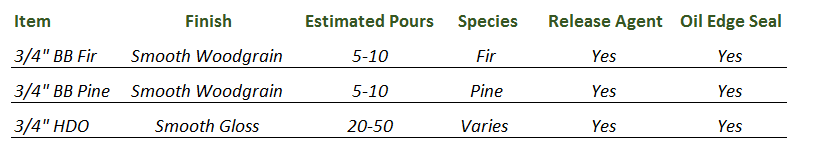

Plyform panels are designed for concrete pouring for foundations, bridges, tunnels, and more. Each panel has a special finish and release agent that is uniquely designed to maximize the number of pours and quality of finish.

Available Sizes:

Frequently Asked Questions:

Q: How many times can you re-use plyform panels.

A: It depends on what type of panel you use and what type of look you are trying to achieve. But in general, a BB plyform panel will get you 5 uses per pour with good care, and an HDO plyform panel can get you 20+. Panels can be finicky, and some might yield just a few, and others many - so this is just a general average.

Q: Do I need to apply a release agent to these panels?

A: All of these come with a factory applied release agent. If inventory has been well covered, they should pour just fine. If the material is older or has been used before on previous jobs, it is possible you'll need to re-apply a new release agent before pouring.

Q: Are all of these panels edge sealed?

A: Yes.

Q: I want the smoothest, best possible finish - what should I use?

A: You should use the HDO plyform panel. HDO panels use a special face that is heat bonded to the veneer panel for a consistent and impeccably smooth finish.

Q: Can I rip the panels to size for special pours?

A: Yes, but be aware that you will lose your edge seal when the panel is cut. Try to align the panel so that the newly cut edge is above the concrete pour if you plan to use multiple times.

Q: What is the difference between the Fir and Pine BBOES?

A: Typically you are able to get more pours of the Fir BBOES and it leaves a smoother finish than the pine. The pine is traditionally lower in price.

HDO Smooth Gloss Finish:

BBOES Smooth Woodgrain Finish:

Fir BBOES:

Pine BBOES:

HDO:

HDO Face: