Fir Plywood

Douglas Fir plywood is cut and milled in the Pacific Northwest. Douglas Fir is inherently strong and has a large diameter log; when used for plywood, it produces a sheathing product that is naturally strong, visually appealing, and very reliable.

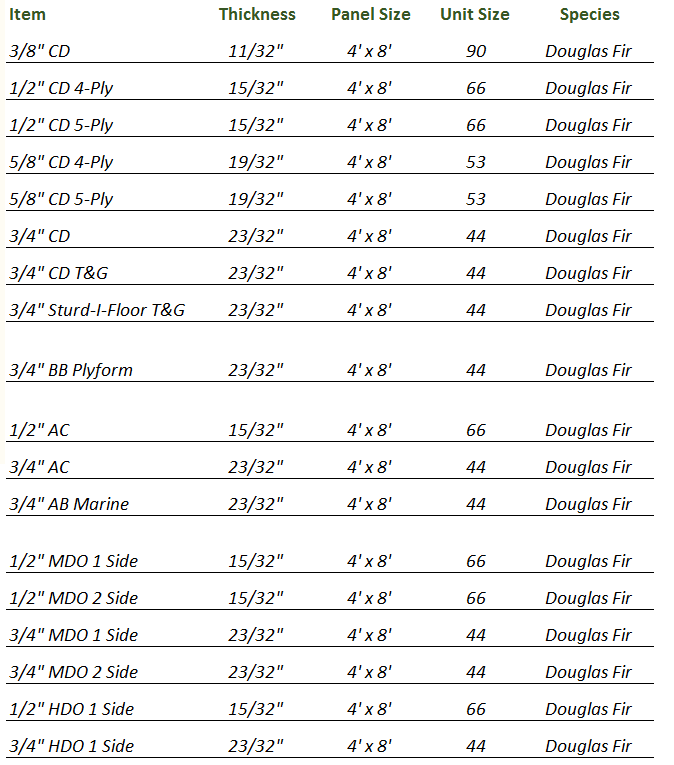

Available Sizes:

Features & Benefits:

-Strong, stiff, and sturdy

-Less susceptible to warping than Yellow Pine

-Ideal for roof sheathing

-Available in multiple grades

Fir Plywood - Safety Data Sheet

Fir Plywood Flooring Installation

Underlayment Installation Tips

Roof Sheathing Installation Tips

Grade Descriptions and Applications

"CD"

-C-grade veneer face, D-grade back, exterior glue. Used for exterior wall sheathing, roofing, and underlayment

"AC"

-A-grade veneer face with a C-grade back. Used for cabinets, soffits, furniture, countertops and other applications where a premium face is required. A-face has any imperfections and knots removed and replaced with patches.

"AB Marine"

-A-grade veneer face with a B-grade back. Exterior rating and uses an exterior glue that is a water-resistant adhesive. Used for hulls of boats and other applications where a watertight panel is necessary.

"BB Plyform"

-B-grade veneer face and back. This product has an oiled face and is used for concrete forming. A typical BB Plyform panel can be re-used up to 7-8 times when handled correctly. BB Plyform leaves a slight wood grain finish.

"MDO"

-Stands for Medium Density Overlay. This panel will have a fine cardboard like face on a regular CD panel. The face is smooth and takes paint exceptionally well. Used for signboards and can also be used for concrete forming.

"HDO 100/30"

-Stands for High-Density Overlay. HDO has a specially engineered face designed for multiple reuses during concrete forming. Leaves a "steel-form" finish after pouring.

Fiber Source